Technology (Polycrack)

Mixed Waste to Energy (Electricity, Light Diesel Oil, Natural Gas, Green Hydrogen)- Polycrack Technology (Process)

- World’s 1st heterogeneous catalytic process (USA patent)

- Can reform any Hydrocarbon waste (rubber, plastic, municipal waste, organic waste & sludge waste) into Light Diesel Oil (LDO), Gases, Green Hydrogen, Electricity, Carbon & Water.

- We can use Light Diesel Oil & Natural Gas to produce electricity. Natural Gas can be further separated into Green Hydrogen, Nitrogen, Methane, etc. or Natural Gas can be compressed into Liquified Petroleum Gases.

- Polycrack technology-based plants use thermally assisted catalytic process (thermal cracking process), with an operating temperature from 450 OC to 700 OC (depending on the type of waste).

- Waste Plastics

- Rubber Tyres

- Municipal Solid Waste

- Petroleum Industry

- Refining Waste

- Packaging

- E-waste

- Agro Plastics

- Organic Waste

- Fats & Grease

- Frac Sludge

- Oil Shale

- ETP Waste

- Rigid Industrial Waste

Heterogeneous Catalytic Conversion

Liquid Hydrocarbon Oil

Mixed Hydrocarbon Gas

Carbon

Water

Example of a 50 Ton per day (TPD) Plant

No. |

Waste |

Output |

Electricity |

|---|---|---|---|

1 |

MSW/Rubber/Tyres |

Light Diesel Oil, Gas, Water & Carbon |

42 MW Electricity |

2 |

Municipal Waste (MSW) |

Light Diesel Oil, Gas, Water & Carbon |

63 MW Electricity |

* 2 MW per day required to run the Plant

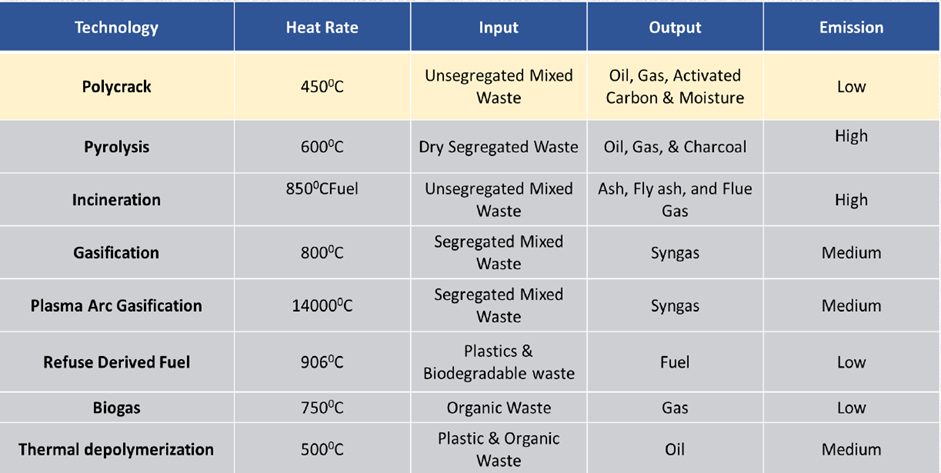

Comparison of Polycrack Vs. other Technologies

Parameter |

Polycrack |

Pyrolysis |

Gasification |

Plasma Arc Gasification |

|---|---|---|---|---|

Temperature C° |

350 - 500 |

400-900 |

500-1800 |

1200-2000 |

Pressure (bar) |

No additional pressure |

1 |

1-45 |

1 |

Emissions |

All readings much below permissible limits |

low emissions |

All the pollutants are lower than the values established by the Brazilian legislation |

Syngas |

Agents |

No need for O2 and Water |

Inter/nitrogen |

Gasification agent O2 , H2O |

Gasification agent: O2, H2O |

Process Products |

||||

Products |

Light Diesel Oil, Gas, Water , Carbon |

Heat, Combustible Gas & Combustible fuel |

Heat & Combustible Gas |

|

Water Generation |

Produces water from the moisture content in MSW |

No water production |

No water production |

|

Gas |

Mixed Hydrocarbon gas (C1-C6) |

H2 , CO, H2O, N2 , Hydrocarbon |

H2 , CO , CH4 , CO2 , H2O & N2 |

H2 , CO , CO2 , CH4 , H2O & N2 |

Solid |

Residue (Carbon) |

Ash, Coke |

Slag, ash |

Slag, ash |

Liquid |

Light Diesel Oil & Water |

Pyrolysis Light Diesel Oil & Water |

|

|

Oxidizing Agent |

Absence of oxygen |

Absence of oxygen or Steam |

Less than Stoichiometric oxygen* or steam as the oxidizing agent |

|

Feed Stock |

Unsegregated MSW with moisture up to 50% |

Segregated and dried specific input. |

|

|

Particles size |

All particle size |

3-6 mm |

|

|

System Capacity |

Modular system |

Fixed capacity |

|

|

Summary

Mixed Waste to Light Diesel Oil & Gases

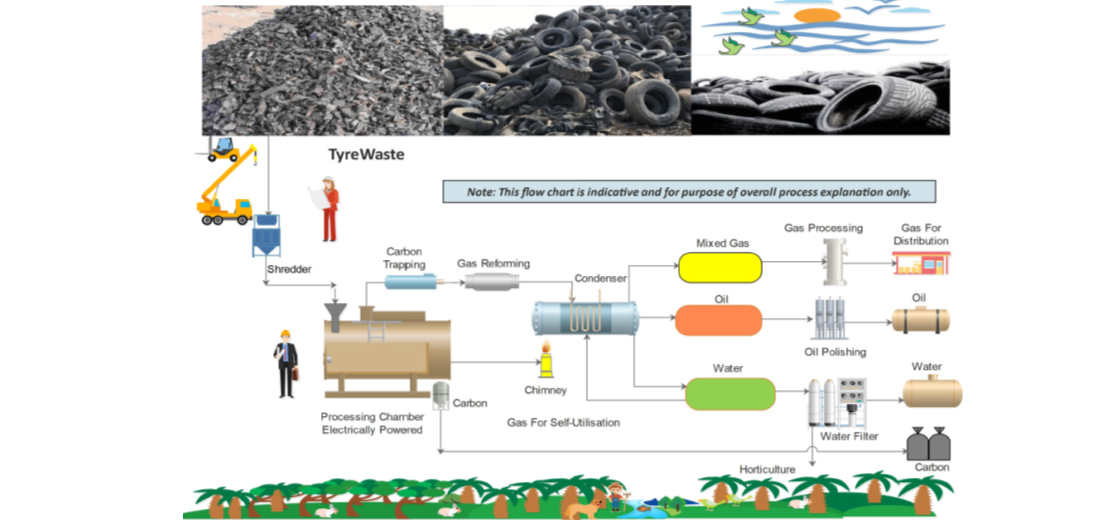

Processing Tyre Waste

Output Utilization Options

Input |

Output |

Utilisation/ Extraction |

End Use |

|---|---|---|---|

MSW |

|

|

|

Municipality Solid Waste containing Organic, plastic, rubber, textile, paper, cardboard etc. |

Mixed Hydrocarbon Gas |

Electricity |

|

Mixed Gas for Extraction |

|||

H2 |

H2-Fuel Cell - To Electricity Aircraft /Buses / Trains/ Industries/ Cooking gas |

||

CO |

Industrial Combustible gas |

||

N2 |

Industrial application in cooling / blanketing/ others |

||

CO2 |

Industrial Applications |

||

O2 |

Industrial/Domestic/Health Care |

||

Balance Mixed Gas containing - C1 to C4 |

Electricity /Kitchen Gas/Other Industrial heating application |

||

Liquid Hydrocarbon (Oil) |

|

Electricity / Industries heating application |

|

Carbon |

|

Bio-Char in agriculture Filtration Media Energy Production |

|

Water |

|

Potable Water H2 By Electrolysis |

|

Biomass |

|

|

|

Agri waste / Harvest / Horticulture Waste |

Mixed Hydrocarbon Gas |

Electricity |

|

Mixed Gas for Extraction |

|

||

H2 |

H2-Fuel Cell - To Electricity Aircraft/Buses/Trains/Industries/Cooking gas |

||

CO |

Industrial Combustible gas |

||

N2 |

Industrial application in cooling / blanketing/others |

||

CO2 |

Industrial Applications |

||

O2 |

Industrial/Domestic/Health Care |

||

Balance Mixed Gas containing - C1 to C4 |

Electricity /Kitchen Gas/Other Industrial heating application |

||

Carbon |

|

Bio-Char in agriculture Filtration Media |

|

Water |

|

Potable Water H2 By Electrolysis |

|

|

|

|

|

Mixed Plastic / Rubber / RDF |

|

|

|

Mixed Plastic /Rubber /RDF containing mixed plastics, rubber, textiles, paper, card board after segregating organic waste from MSW |

Mixed Hydrocarbon Gas |

Electricity |

|

Mixed Gas for Extraction |

|

||

H2 |

H2-Fuel Cell - To Electricity Aircraft/Buses/Trains/Industries/Cooking gas |

||

CO |

Industrial Combustible gas |

||

N2 |

Industrial application in cooling / blanketing/others |

||

CO2 |

Industrial Applications |

||

O2 |

Industrial/Domestic/Health Care |

||

Balance Mixed Gas containing - C1 to C4 |

Electricity /Kitchen Gas/Other Industrial heating application |

||

Liquid Hydrocarbon (Oil) |

|

Electricity / Industries heating application |

|

Carbon |

|

Filtration Media Energy Production |

|

Water |

|

Potable Water H2 By Electrolysis |

Advantages

Eco - Friendly

- No Dioxins and Furans

- Low PM count

- Low Nitrogen Oxide & Sulphur Oxide emissions

- Low Toxic Metals

- All readings & emissions below permissible limits worldwide

Easy & Safe to Use

- No Dioxins and Furans

- Low PM count

- Low Nitrogen Oxide & Sulphur Oxide emissions

- Low Toxic Metals

- All readings & emissions below permissible limits worldwide

Site Friendly

- Enclosed Plant Setup ensures dust free environment

- No foul smell as no biological decomposition eliminated

- Same Day processing of waste eliminates the landfill practice

Cost Effective

- Low Capital Investment

- Low operating cost

- Relatively Lower temperature is required in the process which results in lesser energy requirement